How Shat·R·Shield Lighting Inc. Shattered Expectations and Standards for Corrections Lighting

Photo: The plant in Salisbury, N.C., where Shat·R·Shield manufactures its line of detention-grade correctional lighting. | Photo Credit: (All) Shat·R·Shield

By CN Staff

Shat·R·Shield didn’t set out to be a player in correctional lighting. The North Carolina-based lighting manufacturer had already been an innovator in the lighting industry for 50 years when a correctional facility official reached out with a problem: Their facility included fixtures that were being tampered with and compromised, and the lights were not performing to expectation. Shat·R·Shield was already known for shatter-resistant fluorescent lamps and polycarbonate LED fixtures, so they listened and aimed to create something better.

“We found out what their problems were, what issues they had with their current lighting,” said Karen Clouse, president of Shat·R·Shield. “And through collaboration with them and our product development team, we designed a fixture that would help resolve all those problems.”

Due to outside forces, however, it wasn’t a smooth entrance to the market. Soon after Shat·R·Shield’s first correctional product launch, COVID-19 hit. The company had to navigate remote marketing and limited ability to access facilities. But the word had begun to spread. Facility staff started testing the lights—sometimes just in one cell or shower—and slowly the orders came in.

Now, correctional sales account for approximately half of Shat·R·Shield’s total fixture business. Depending on the month, that number can be as high as 70%.

From Shatter-Resistant Lamps to Custom Fixtures

Founded in 1970, Shat·R·Shield originally focused on applying a protective coating directly to fluorescent lamps. This niche made them the world’s leading manufacturer of shatter-resistant lighting. The company still manufactures everything out of a single facility in Salisbury, N.C., and for Bob Nolan, Shat·R·Shield’s chief executive officer, it was a family business. Nolan began working for the company when he was 11 years old.

“It is my dad’s business,” he said. “I’ve been here for 42 years.”

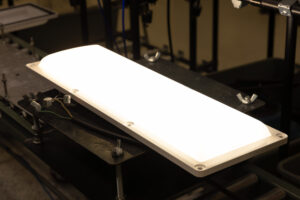

Evolving into an LED fixture manufacturer wasn’t an overnight process. It required dedication and significant planning. Rather than importing generic parts or mass producing commodity products, Shat·R·Shield chose to focus on highly specialized solutions that addressed specific problems. These include graphite-infused polymer housings, thick polyurethane lenses, and a patented LED coating process that protects fragile chips from moisture and corrosion.

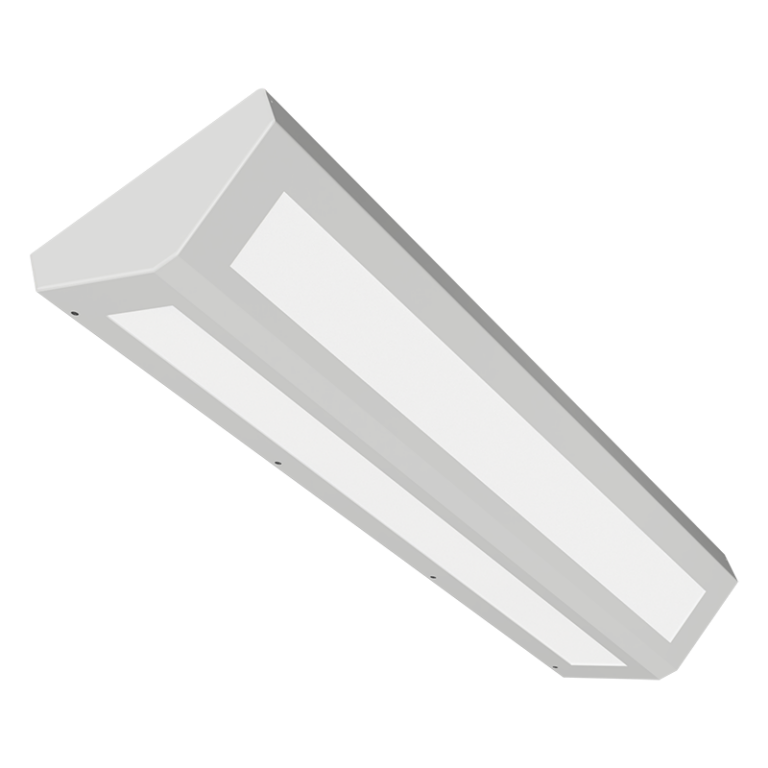

Within the correctional space, the company has a clear goal: To build a light that’s tamper-proof, ligature-resistant and able to withstand a serious beating.

“[Our lights] are very low profile,” said Clouse. “Even if an inmate gets into the fixture, they can’t hide contraband or anything inside [because of] the way that they’re designed.”

“Our discipline is to keep a low profile because no one [else] is doing that,” Nolan added. “Everyone else is selling box fixtures. Ours are sleek.”

Listening, Customizing and Delivering

While it isn’t common to see large fixture companies refresh product lines, Shat·R·Shield’s strategy has been to stay small and nimble and to listen to the needs of their users.

“One of the biggest things we’ve discovered is that most of the jobs we go into [in corrections] require some type of custom work with the fixture,” said Clouse.

Older facilities mean outdated lighting infrastructure. Sometimes that means a junction box adaptation, a mounting modification or even full retrofit plates to cover “scars” left by removed fixtures. Other times, it is one of the upgrades a facility can make with year-end funds before the fiscal calendar resets. In any scenario, Shat·R·Shield’s size allows the company to respond quickly.

“Each project is visited by one of our salespeople, and they know there is going to be some degree or modification or adaptation required,” said Nolan. “Custom fixtures amounts to about 90% of our corrections work right now.”

Shat·R·Shield has placed an emphasis on internal coordination. The whole team—including design engineers, operations staff, marketing and sales—participates in product development meetings. The company reduces miscommunications by using an ERP system to align manufacturing, part numbering and build-out timelines.

“We are small, and we are quick to react,” said Nolan. “If someone has an idea and it sounds like a good one, we try it. It doesn’t have to go through a battalion of engineers.”

See the 2025 Regional Edition of Correctional News to read more about Shat·R·Shield’s product development initiatives and rebranding efforts to meet future demands.